The modular vessels will include a variant tailored for the U.S. Navy’s Modular Attack Surface Craft (MASC) programme. Designed for contested waters, MASC aims to create a distributed, autonomous fleet that complements traditional manned warships.

Anduril and HD Hyundai’s ASV will feature a steel hull, open-architecture systems, and a 360-degree field of view to maximise durability and mission flexibility. Payloads for intelligence, surveillance, strike, and electronic warfare can be reconfigured rapidly, allowing dynamic adaptation in complex maritime environments.

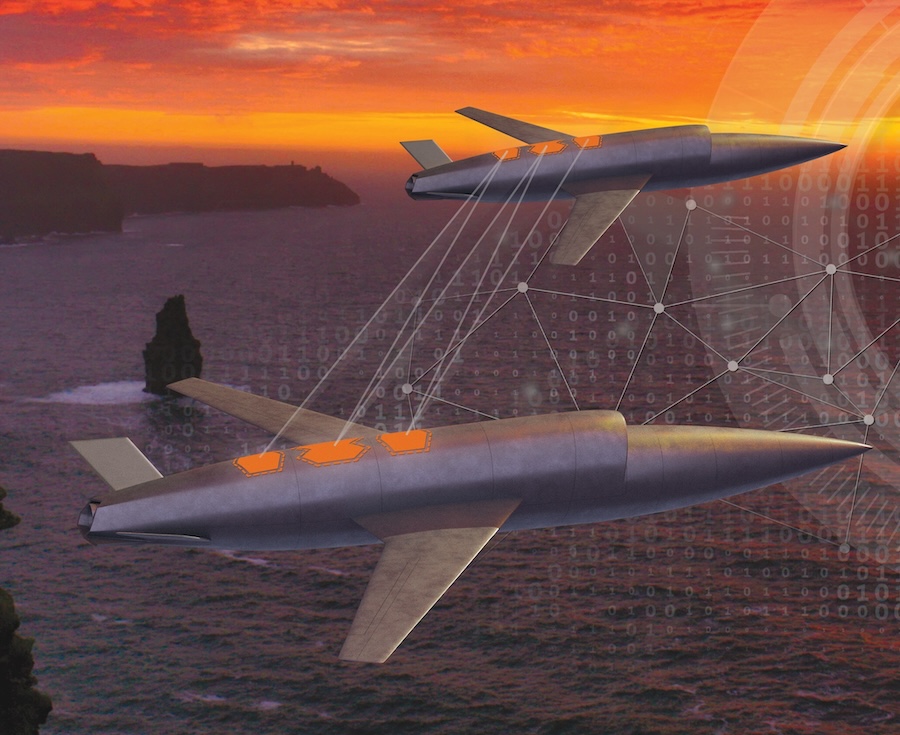

Integrated autonomy software will unify propulsion, navigation, and payload control to enhance situational awareness and responsiveness. The software-defined design also ensures interoperability across hardware and reduces supply chain dependency.

The first ASV prototype is being built in Korea using HD Hyundai’s facilities to validate the design and ship systems integration. Future vessels, including those for the MASC programme, will be fully manufactured in the United States.

Anduril has invested tens of millions of dollars to revive the former Foss Shipyard in Seattle, Washington, as its U.S. base for low-rate assembly and testing. The Pacific Northwest offers the industrial infrastructure and skilled labour needed to scale production.

Hadrian, a manufacturing partner, is contributing automation and precision fabrication to reduce lead times and support scalable production. “Hadrian has been involved in design for producibility from Day 1,” according to the release.

The ASV programme builds on Anduril Maritime’s experience with Ghost Shark, an autonomous undersea vehicle developed with the Royal Australian Navy. This work, alongside Copperhead, Seabed Sentry, Dive-LD, and Dive-XL, reflects Anduril’s strategy of integrating modular platforms with shared software and manufacturing systems.