The Spyder system, manufactured by Israel’s Rafael Advanced Defense Systems, represents a significant modernisation of the Czech Republic’s air defence capabilities. According to Colonel Jaroslav Daverný from the Ministry of Defence’s Force Development Section, the new system provides greater range, improved accuracy, and the ability to engage multiple aerial targets simultaneously, offering enhanced protection against evolving security threats.

The Czech Republic has procured all available missile types for the Spyder system, ensuring maximum operational flexibility. These include the short-range Python 5, the radar-guided I-Derby, and the long-range I-Derby variant, which has a reach of up to 80 kilometres. The versatility of these munitions allows the system to effectively counter a wide range of aerial threats.

A contract for four Spyder batteries was signed in 2021, valued at approximately 13.7 billion CZK, with deliveries set to be completed by 2026. In 2023, an additional order for I-Derby LR missiles was placed. Ammunition deliveries are expected to continue until at least 2027, subject to further procurement options.

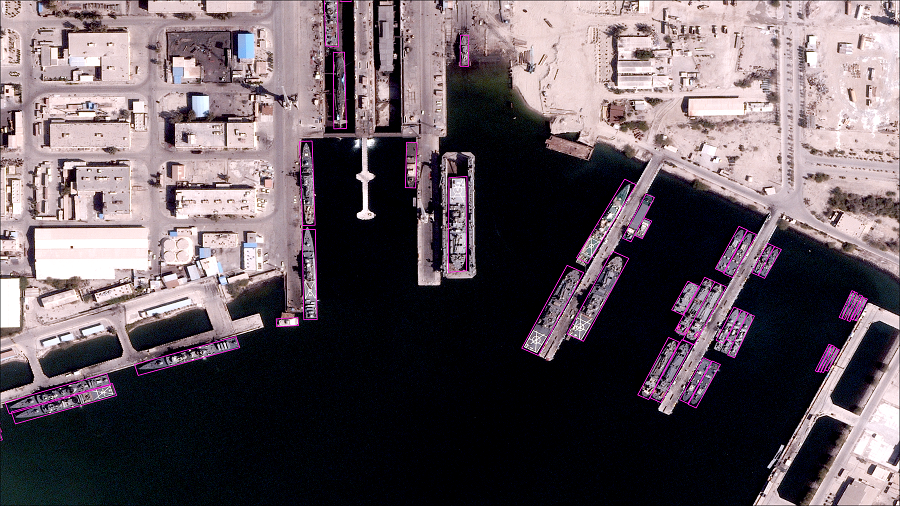

Each Spyder battery consists of nine vehicles, including a radar system, four missile launchers, a transport and loading vehicle, and a command and fire control unit. Additionally, the procurement includes operational and maintenance equipment, as well as spare parts. The systems will be deployed with the 251st Anti-Aircraft Missile Squadron of the 25th Anti-Aircraft Missile Regiment, based in Strakonice.

Factory testing of the first battery is a meticulous process, ensuring all components meet strict quality standards. Each vehicle and its superstructure must undergo inspections to verify functionality and system integration. The Czech Ministry of Defence’s State Quality Verification Authority oversees the locally produced components, while Israeli-manufactured parts are inspected by their respective regulatory bodies. The ministry also supervises the technical certification of electrical, lifting, and pressure systems to ensure compliance with safety and hygiene regulations.

These tests are time-consuming, with each vehicle requiring ten working days to complete verification. Since each Spyder battery consists of nine vehicles, the full factory testing process takes approximately 90 days. Electromagnetic compatibility tests, necessary for system integration into the Czech defence network, are also conducted during this period.

By the end of 2024, factory trials for the first battery are expected to conclude, followed by verification of data transmission capabilities both within the battery and with higher command levels. Security assessments will also be conducted to certify the system for classified military use. Colonel Daverný emphasised that these steps are crucial to ensuring the Spyder system is fully integrated and secure.

Czech military personnel from the 251st Squadron are already beginning familiarisation with the new technology. Their primary training task will take place at the end of 2024, when they participate in operational trials, a necessary step before the system is officially introduced into the Czech Armed Forces’ inventory.

A key aspect of the Spyder acquisition is the involvement of the Czech defence industry, which accounts for over 30% of the project. Local companies, including Vojenský technický ústav and RETIA, are key partners in the system’s production. The manufacturing process is being carried out simultaneously in the Czech Republic and abroad, ensuring efficient delivery and integration of the new air defence capability.