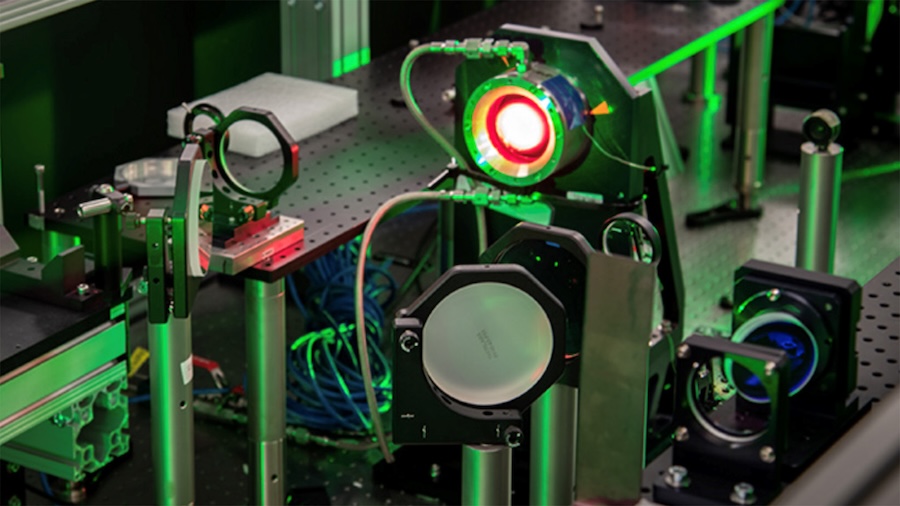

The fuselages were produced without unique tooling or fixturing, using Divergent’s fully digital, software-defined manufacturing assets. Divergent stated that its Divergent Adaptive Production System (DAPS™) integrates AI-driven design, industrial-rate additive manufacturing and universal robotic assembly to create structures developed more quickly, with higher performance and at lower cost than conventional alternatives.

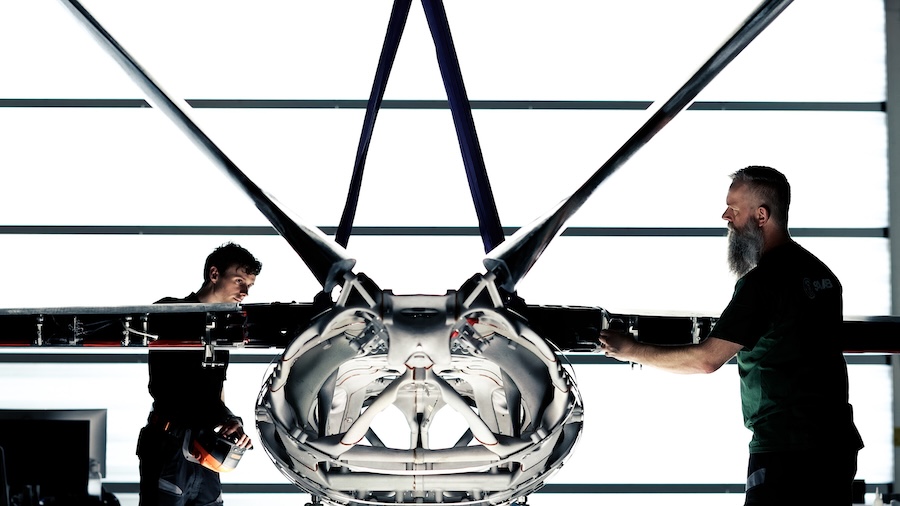

According to the companies, the fuselage will be among the largest laser powder bed fusion structures to undergo powered flight. The 15-foot structure consists of 26 unique printed parts joined and bonded in Divergent’s fixtureless robotic assembly cell, demonstrating the scale and capability of its assembly technology.

“This collaboration with Saab highlights what becomes possible when ambitious aircraft concepts are paired with an end-to-end, software-defined manufacturing platform,” said Lukas Czinger, Co-founder and CEO of Divergent. He added: “By tightly integrating digital design, additive manufacturing, and automated assembly, our teams were able to realize a large-scale fuselage structure aligned with Saab’s vision, while moving with a level of speed, flexibility, and structural integration that traditional approaches cannot match.”

Axel Bååthe, head of Saab’s Rainforest, said: “Adopting Divergent’s additively manufactured and digitally designed structures in this effort has given our joint team unparalleled flexibility in this development process.” He added: “We see digital design and advanced manufacturing as a key enabler of our collaborative success in this project.”

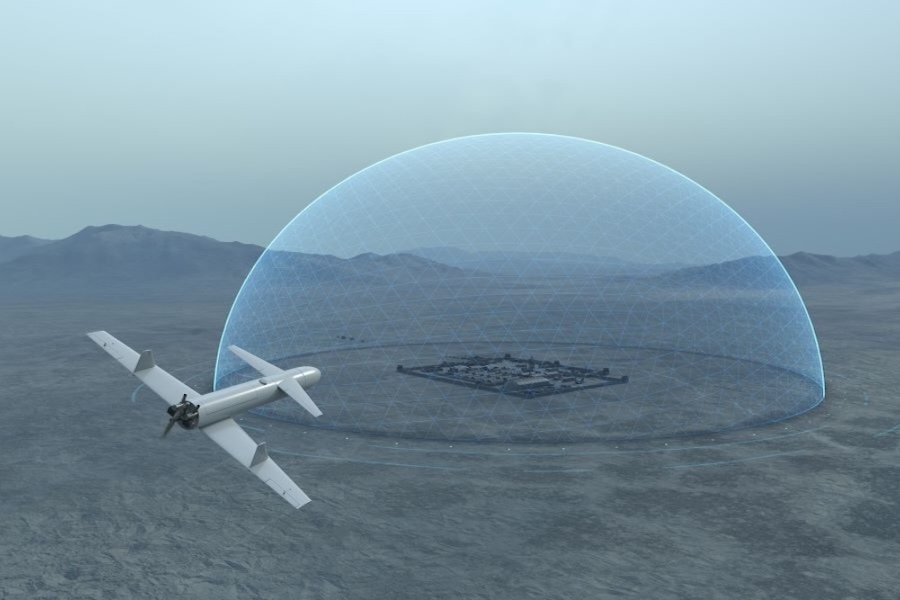

The companies said the delivery of the fuselages highlights the continued expansion of Divergent’s capabilities into more demanding aerospace applications. They expect the structures to support vehicle integration and flight testing for Saab’s conceptual autonomous aircraft.