The company said its approach to additively manufactured solid propellant provides a safe and cost-effective alternative for tactical rocket motors that can be rapidly produced at scale. “This final milestone demonstrates Firehawk’s ability to 3D print propellant for a wide range of ordnance. We’re addressing the Army’s increasing demand for propellant with 21st century propulsion solutions as they ramp up missile production,” stated Will Edwards, CEO, Firehawk.

Edwards added that, “Our innovative in-house fabrication and engineering capabilities allow us to respond quickly with a cutting-edge solution to meet current and future mission needs.” Firehawk previously announced the inaugural flight test of an additively manufactured Guided Multiple Launch Rocket System class Firehawk Analog, a 3D-printed hybrid rocket engine system.

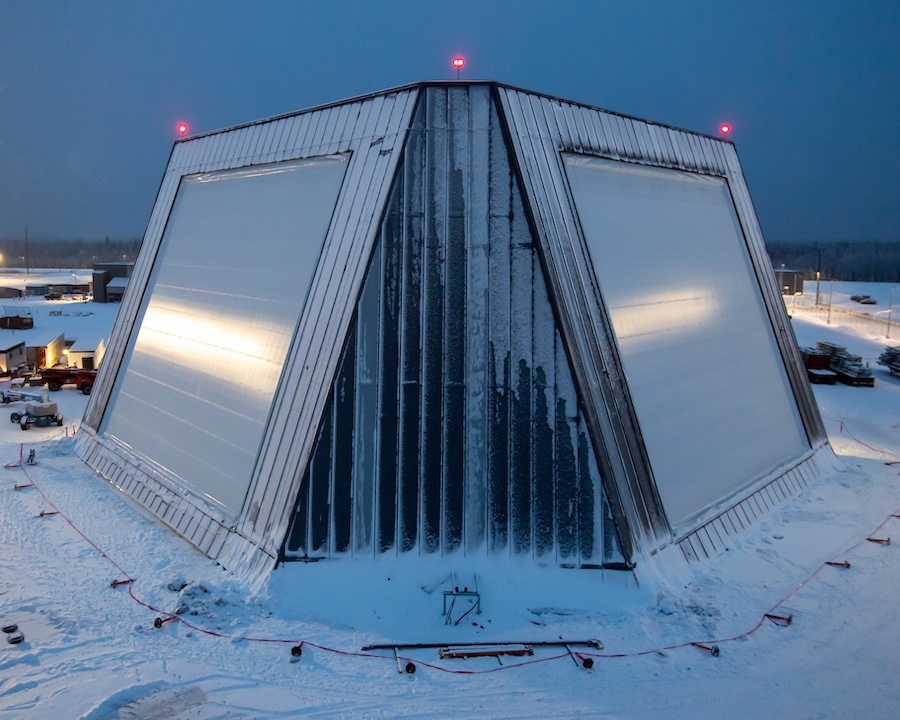

The company said these results demonstrate it can produce tailored performance across multiple propulsion types to serve customers across the defence base. Firehawk is headquartered in Dallas, is building a 340-acre production facility in Lawton, Oklahoma, and conducts static fire and flight tests at two facilities in West Texas, including a 30-square-mile launch range.