The campaign exceeded expectations, showing robust operation and a threefold increase in engine airflow compared with legacy hypersonic demonstrators. According to GE Aerospace, the technology could enable high-speed flight and extended range across a variety of multi-mission platforms.

“We’ve proven that GE Aerospace’s rotating detonation combustion designs are scalable,” said Mark Rettig, vice president & general manager of Edison Works Business & Technology Development at GE Aerospace. “In just 10 months, our team advanced from its legacy ramjet to a 3X scale demonstrator with RDC. This rapid progress underscores the maturity of our technology and the strength of our roadmap toward integrated high-speed propulsion solutions.”

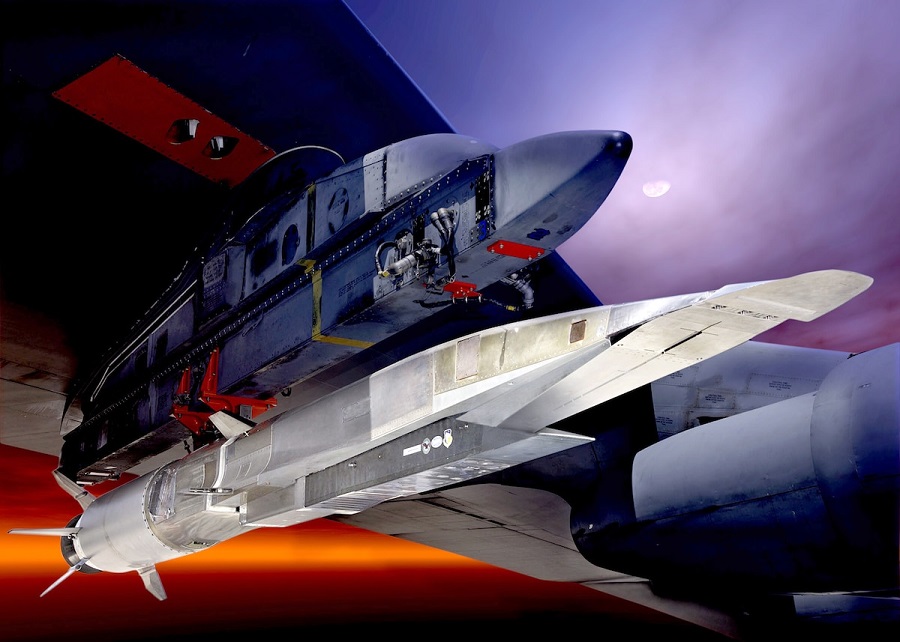

RDC works by combusting fuel and air through detonation waves rather than the deflagration process used in conventional ramjets, allowing higher thrust and improved efficiency in a smaller, lighter engine. Testing of the latest demonstrators began in July at GE Aerospace’s continuous flow, high-speed propulsion facility.

The effort drew on collaboration between GE Aerospace engineers, GE Aerospace-Innoveering – acquired in 2022 for its hypersonic propulsion expertise – and the company’s research centre. These tests follow the 2024 milestone when a hypersonic dual-mode ramjet progressed from concept to testing in less than 11 months.

GE Aerospace’s Edison Works, the advanced design, engineering, and technology arm of the company, led the development. With a focus on rapid prototyping, digital engineering, and innovation, Edison Works aims to push the boundaries of defence propulsion and define the future of flight.