The importance of metal components in defence technology

Modern defence systems require materials that can withstand extreme conditions while maintaining structural integrity. High-strength metals such as titanium, aluminium alloys, and specialised steel provide:

- Durability: Metal components can endure harsh environments, including extreme temperatures, corrosion, and heavy impacts.

- Lightweight Properties: Advanced alloys reduce the weight of military equipment, enhancing mobility and fuel efficiency.

- Versatility: Metals can be precisely machined and fabricated to meet the unique requirements of defence applications.

If you would like to learn more about this topic, visit our partner’s website, Elektron, for comprehensive insights into advanced metal components.

Applications of metal components in defence

Metal components are integral to various defence applications, including:

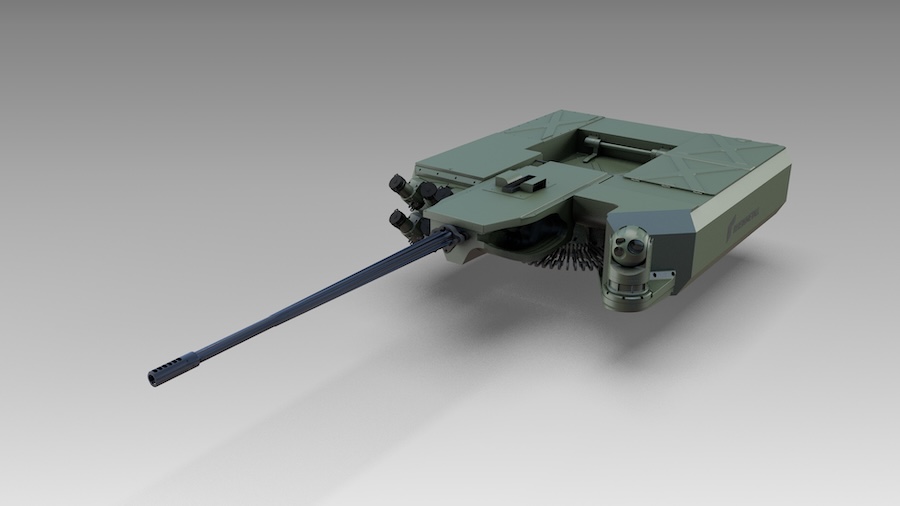

- Armoured Vehicles: High-strength steel and composite metal alloys provide protection against ballistic threats while maintaining manoeuvrability.

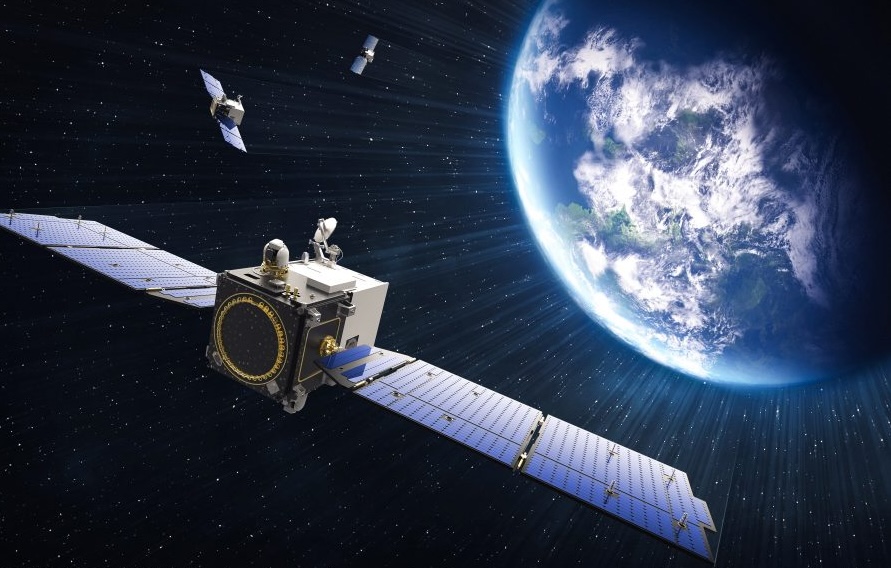

- Aerospace Technology: Aircraft structures, landing gear, and engine components rely on lightweight yet durable metals to ensure optimal performance and safety.

- Naval Engineering: Ships and submarines utilise corrosion-resistant metals to withstand the challenges of marine environments.

- Weapons Systems: Precision-machined metal components are used in firearms, artillery, and missile systems for reliable performance.

Innovations in metal fabrication for defence

Technological advancements in metal fabrication are driving the defence industry’s ability to produce more sophisticated and effective systems. Some key innovations include:

- Additive Manufacturing (3D Printing): Allows for the production of complex geometries with reduced material waste and enhanced design flexibility.

- Nanostructured Materials: Improve the strength-to-weight ratio and durability of defence components.

- Automated Precision Machining: Ensures the highest levels of accuracy and consistency in manufacturing critical defence components.

These innovations enable defence manufacturers to produce lightweight, strong, and highly reliable equipment tailored to the ever-evolving battlefield requirements.

Challenges in metal component production for defence

Despite the numerous benefits of using metal components in defence applications, several challenges must be addressed, including:

- Supply Chain Security: Ensuring a stable and reliable supply of high-quality metals is crucial for defence readiness.

- Cost Management: The use of advanced materials can be expensive; balancing performance with budget constraints is a key consideration.

- Compliance with Regulations: Defence components must adhere to stringent international standards and certifications.

Addressing these challenges requires collaboration with trusted suppliers who understand the unique needs of the defence sector.

Conclusion

Advanced metal components are at the heart of modern defence systems, providing the strength, durability, and flexibility required for military operations. As the industry continues to evolve, innovations in metal fabrication will play a crucial role in enhancing the effectiveness and efficiency of defence technologies.

For more information about high-quality metal components for the defence industry, visit https://webelektron.com/.

![Air and missile defense: IBCS and the future of offensive and defensive integrated fires [Behind the Frontlines]](https://defence-industry.eu/wp-content/uploads/2025/07/Northrop-Grumman-completes-delivery-of-Integrated-Battle-Command-System-IBCS-units-for-U.S.-Army.jpg)