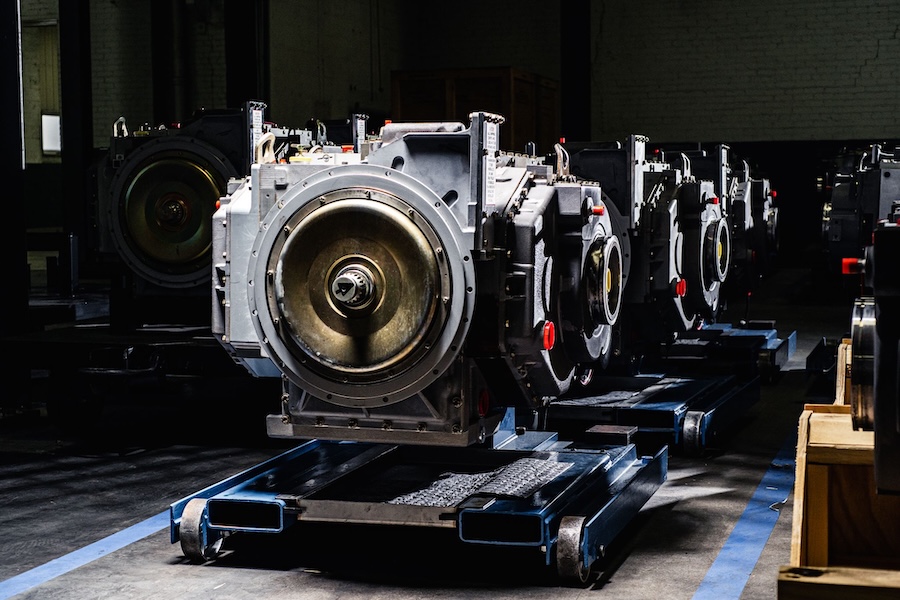

BMC told defence publication Shephard Media that “we hope to announce the delivery of the New Altay MBT very soon,” referring to the T1 configuration powered by a South Korean 1,500-horsepower DV27K diesel engine and EST15K transmission. The company stressed that this solution addresses delays experienced during local engine development.

According to the current production roadmap, 85 units of the Altay T1 will be delivered out of a 250-tank order, with the remaining 165 to be manufactured as Altay T2s featuring the indigenous BATU engine. The Turkish Defence Industry President Haluk Gorgun announced in February 2025 that three Altay tanks would enter the inventory during 2025.

The planned schedule sets deliveries of three units in 2025, 11 in 2026, 41 in 2027, and 30 in 2028, completing the T1 batch. From 2028 onwards, the Altay T2 is expected to enter service, equipped with the 1,500-horsepower BATU engine currently undergoing final testing by BMC Power.

The Altay programme is presented as the most concrete step towards Türkiye’s goal of eliminating foreign dependency in armoured platforms. BMC continues its design and testing efforts to meet this objective and provide a fully indigenous solution for the Turkish Land Forces Command.

Named after General Fahrettin Altay, the 65-ton third-generation tank is designed to compete with models such as the M1 Abrams and Leopard 2. It is equipped with a 120mm L/55 smoothbore cannon made by MKE, Roketsan’s modular composite armour, and Aselsan’s AKKOR Active Protection System providing 360-degree defence.

The vehicle has a top speed of 65 km/h, an operational range of 450 kilometres, and operates in temperatures from -32°C to +52°C. Its advanced fire control systems and network-centric capabilities are designed to increase combat effectiveness across varied operational environments.

Source: Türkiye Today.

![Inside Operation Roaring Lion: IDF launches largest air campaign in history, striking over 500 targets in Iran [VIDEO]](https://defence-industry.eu/wp-content/uploads/2026/03/operation-roaring-lion-idf-launches-largest-air-campaign-in-history-striking-over-500-targets-in-iran-video.jpg)