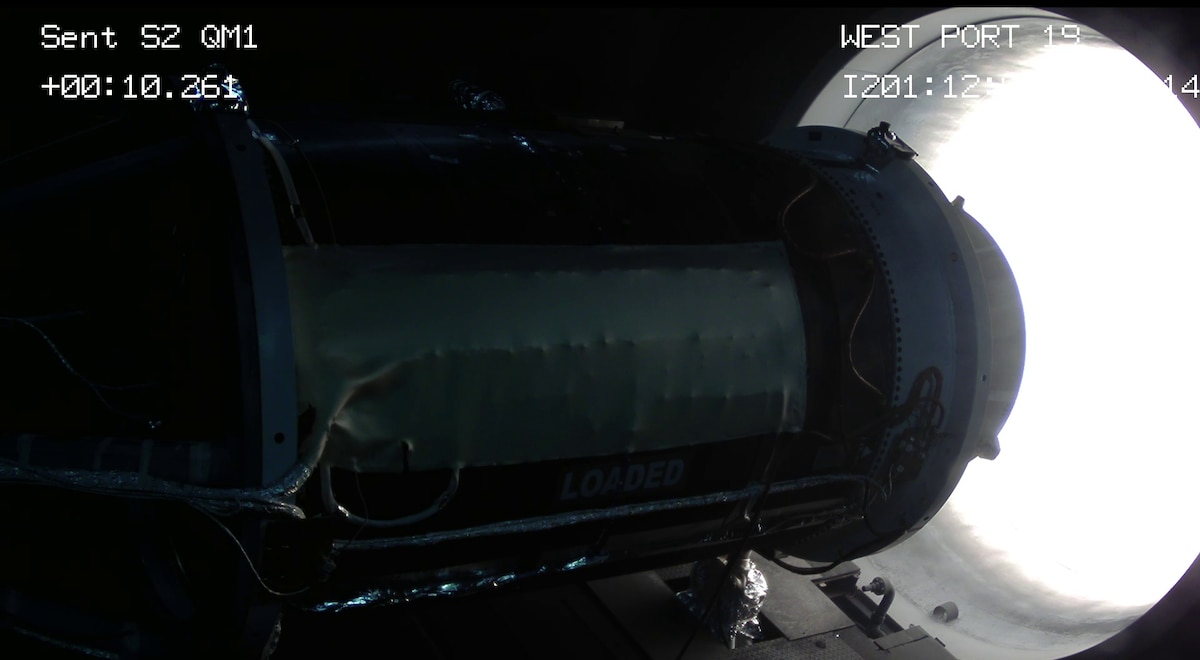

To replicate high-altitude conditions, the motor was tested in a vacuum chamber, allowing engineers to gather vital data on thrust, burn characteristics, and steering performance via its thrust vector control system. The motor is one of three booster stages in the Sentinel missile and this qualification test is part of a broader effort to validate digital performance models.

“This test reflects our disciplined digital engineering approach and the continued momentum behind the Sentinel program,” said Brig. Gen. William S. Rogers, Air Force programme executive officer for ICBMs. “We’re not just testing hardware — we’re proving that our models are accurate, our development timeline is achievable, and the system will be ready to deliver when called upon.”

Data collected will be used to refine the stage-two motor design and reduce technical risk ahead of production. The testing also supports verification of predictive models built in a digital engineering environment.

The latest milestone follows a successful stage-one motor test conducted in March at Northrop Grumman’s facility in Promontory, Utah. That earlier test confirmed the motor’s performance and consistency with digital simulations, laying the groundwork for the current phase.

“This isn’t just about one motor test,” Rogers added. “It’s about building confidence — in our engineering; in our program schedule; and, most importantly, in our ability to deter aggression and defend the nation.”

The Sentinel programme employs a model-based design process to enhance system simulation accuracy and reduce dependence on costly physical prototypes. Additional stage-two qualification tests are planned throughout the year to assess motor components under various environmental conditions.