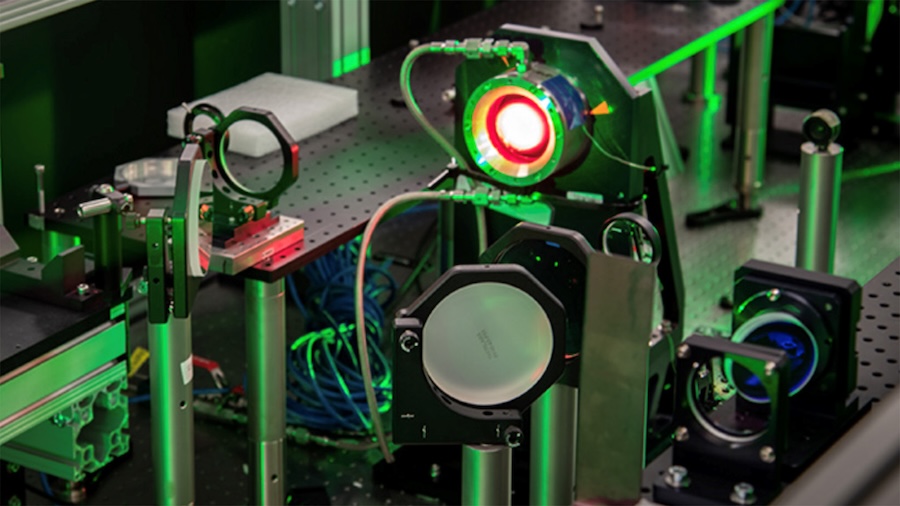

Central to the initiative are the LM2500 and LM6000 industrial gas turbines, which are aero-derivatives of GE Aerospace aircraft engines adapted for marine operations. MTU already manufactures components for both models and provides maintenance services worldwide.

Gas turbines are widely deployed in military naval fleets, valued for their high power density and performance. The LM2500 from GE Aerospace could play a central role in powering the German Navy’s next-generation F127 frigates, of which at least five units are currently being procured.

A decisive factor for successful deployment is MTU’s global service network, with facilities and expert teams across five continents. This enables the company to deliver operational support wherever required.

MTU has been a trusted propulsion partner of the German armed forces for decades, particularly in aviation. “MTU and the German armed forces have successfully cooperated in engine maintenance for more than 20 years. MTU employees and Bundeswehr personnel work hand in hand,” said André Sinanian, Managing Director and Senior VP of MTU Maintenance Berlin-Brandenburg. “Together with GE Aerospace, we now intend to transfer this aviation expertise to the naval domain – supporting German and international naval forces with proven technology and reliable service.”

Component production and maintenance will be complemented by turbine packaging, which prepares systems for deployment in power plants or aboard ships. GE Aerospace and MTU are examining opportunities to centralise this packaging work at MTU Maintenance in Ludwigsfelde for the global market outside the United States.

“We are pleased to continue to grow our relationship with MTU as a premier service provider for the LM product portfolio. MTU is the ideal partner for us in the naval sector: technologically outstanding, closely connected with the German military, and globally positioned with strong service capabilities,” said Mark Musheno, Vice President Sales & Marketing at GE Aerospace. “The LM2500 continues to bring advanced aviation technologies to energy markets and naval propulsion. Given our longstanding collaboration in Aerospace, MTU expanding into the maritime sector is the logical next step – both strategically and technologically.”

Maintenance work in Germany is centred at MTU’s Ludwigsfelde site, where the company is investing in additional capacity. Over the coming years, MTU aims to increase its maintenance output for LM-series gas turbines by 30 percent compared with 2024.

MTU and GE Aerospace also share a five-decade partnership in civil and military aviation. MTU has contributed to the development and production of long-haul aircraft engines for Airbus and Boeing, while maintaining GE Aerospace models ranging from the CF6 to the GEnx. In the defence sector, the companies collaborate on fighter jet engines and jointly power the CH-53K heavy-lift transport helicopter.