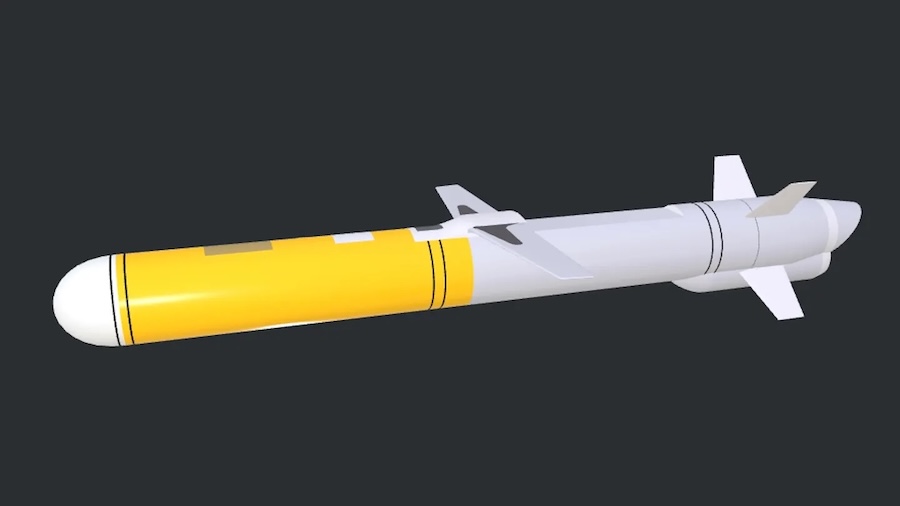

The Skelmir S12 is designed with a 12.75-inch diameter, offering unprecedented flexibility and performance within the underwater technology sector. It is unique in its ability to be deployed from submarines, surface vessels, and aircraft, serving multiple mission profiles including torpedo operations, sensor platforms, and electronic warfare.

Nelson Mills, co-founder and CEO of Vatn Systems, stated: “With the Skelmir S12, we set out to fill a critical market void—creating a vessel that merges the capabilities of a traditional AUV with the agility and performance of a lightweight torpedo for a fraction of the cost.” He highlighted the platform’s superior payload capacity, flexible deployment, and cost-effectiveness compared to existing solutions.

Mills also emphasised the scalability enabled by the new manufacturing facility, saying: “We’re excited to be able to produce these at scale in our new manufacturing facility to fill that gap in the market and meet customer demand starting this summer.”

The AUV configuration of the Skelmir S12 has already completed its first exercise successfully. The first production run has been sold to government customers, with deliveries anticipated within the year. The torpedo variant is expected to follow next year.

Vatn Systems’ new manufacturing facility employs modular design and vertical integration techniques, setting a new benchmark in underwater vehicle production. Brendan Smith, Director of Manufacturing at Vatn Systems, remarked: “With current industry standards at about 200 vehicles per year, this facility will enable a strong competitive differentiation for us as we scale production capacity to 2,000+ vehicles annually to meet growing customer demand.”

Smith, who previously worked at Boston Dynamics, highlighted the efficiency of the new facility: “By leveraging modular design and vertically integrated production, we’re able to reduce lead times, minimise handoffs, and eliminate many of the inefficiencies common in traditional assembly processes.” He pointed out that this approach provides better quality control, faster iteration cycles, and the ability to scale output in response to increasing demand.

With the new Skelmir S12 product line and manufacturing facility, Vatn Systems aims to solidify its position as a leader in the defence and underwater vehicle markets. The company is poised to meet growing demand while delivering innovative and versatile underwater solutions.

Source: Vatn Systems (press release).