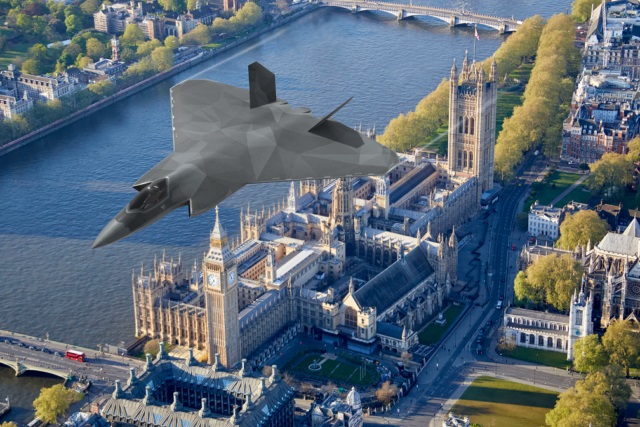

As part of the Future Combat Air System (FCAS) programme, Orpheus is being used to test next-generation technologies. This recycling method indicates the possibility of producing components for the future Tempest combat aircraft, aligning with Rolls-Royce’s Grow Combat strategy.

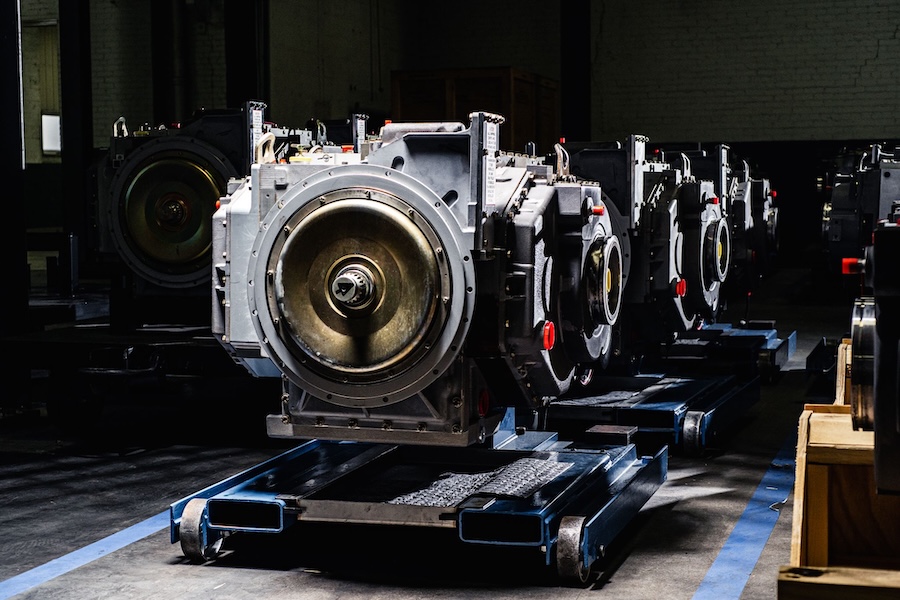

The Ministry of Defence (MOD) holds surplus assets containing valuable metals such as steel, aluminium, and titanium. The Tornado 2 Tempest project team assessed whether these components could be atomised into powders, known as feedstock, for additive manufacturing.

Tornado components with significant titanium content, including jet engine compressor blades, were cleaned and atomised. This process resulted in the creation of a 3D-printed nose cone and compressor blades, demonstrating the feasibility of recycling materials for aerospace applications.

Rolls-Royce installed the 3D-printed nose cone onto an Orpheus test engine and conducted operational tests. The results confirmed its safety and functionality, supporting further exploration of this method for future aircraft.

The project was a collaboration between Defence Equipment and Support’s (DE&S) Defence Recycling & Disposals Team (DRDT), the MOD FCAS team, Rolls-Royce, and Additive Manufacturing Solutions Limited (AMS). AMS, based in Burscough, Lancashire, provided expertise in additive manufacturing for this initiative.

Funded by UK Strategic Command’s Defence Support Organisation under its Circular Economics for Defence Concept Note, the project highlights the potential for material reuse in the defence sector. This approach could enhance the UK’s access to strategic metals and reduce reliance on external supply chains.

Andrew Eady, Rolls-Royce VP FCAS Sustainability, described the project as an example of sustainable innovation in defence. He emphasised Rolls-Royce’s focus on circular economy practices and digital advancements to support efficiency and sustainability.

As part of the project, a Digital Product Passport was implemented to record material provenance and lifecycle data. This tool could help improve transparency in material allocation and prevent counterfeit components from entering the supply chain.

Thomas Powell, DRDT’s Strategic & Submarine Recycling Senior Commercial Manager, highlighted the benefits of the initiative. He noted that recycled components could reduce costs and resource reliance while also improving performance through lighter and more durable parts.

The project involved over 80 personnel, including DRDT’s commercial graduates and Rolls-Royce apprentices, fostering collaboration between experienced professionals and emerging talent. This effort aims to develop sustainable solutions for future defence capabilities.

Squadron Leader Rob, FCAS’ Sustainability Requirements Manager, noted the potential of the project to improve RAF supply chain efficiency while reducing emissions and waste. He acknowledged that access to critical materials may become more challenging, making projects like Tornado 2 Tempest increasingly relevant.

The Ministry of Defence recognised the project by awarding Rolls-Royce a Chief of Defence Logistics and Support (CDLS) Commendation. This acknowledgement highlights the initiative’s role in advancing sustainability within defence logistics.

AMS Director Robert Higham stated that the project allowed AMS to demonstrate its circular economy capabilities in defence. He expressed appreciation for the opportunity to showcase innovative recycling solutions in collaboration with the MOD and Rolls-Royce.