NATO is continuously looking to exploit new technologies that have the potential to address the needs of military logistics chains. Additive Manufacturing, commonly known as 3D printing, has been identified as an emerging and disruptive technology with the potential to improve readiness, reduce obsolescence issues, decrease sustainment costs, compress the supply chain, and enhance warfighting capability.

To improve interoperability between different national efforts in the field of Additive Manufacturing, NSPA was tasked by ACT in January 2023 to develop a digital platform where nations and industry can collaborate, request and share files used for Additive Manufacturing. Nations and the defence industry are gradually adopting this technology due to its many benefits, including the ability to print spare parts on-site and on-demand.

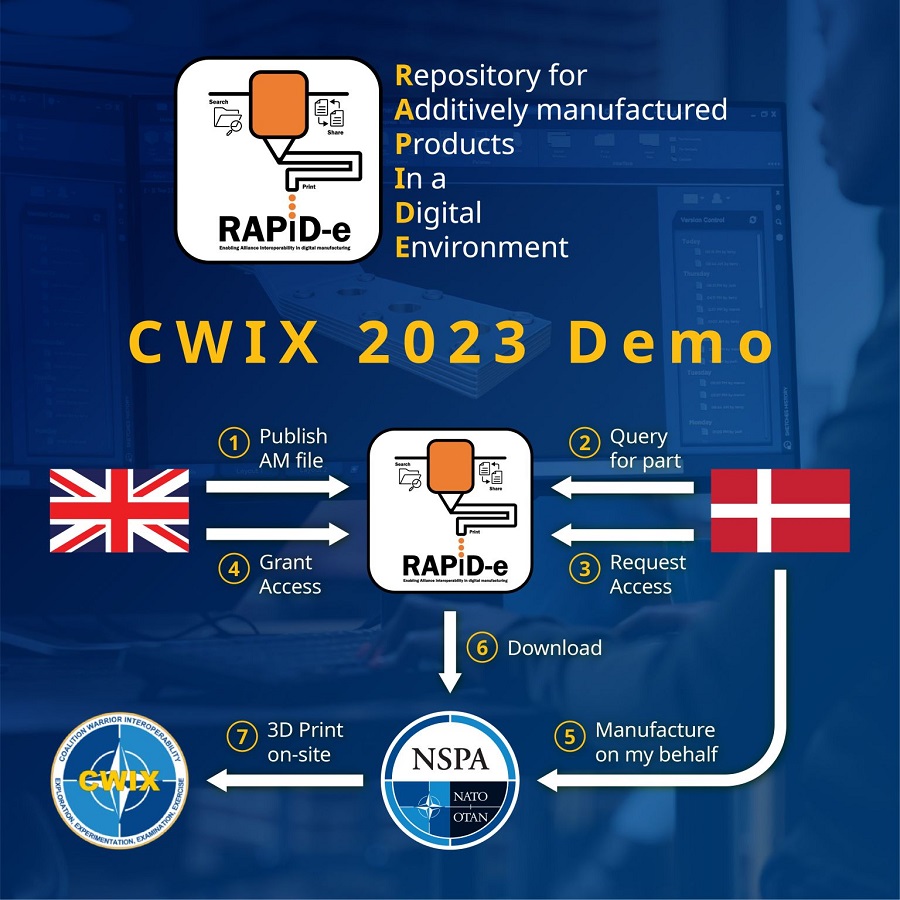

Capitalising on its existing portfolio of digital hub solutions, NSPA has designed a Proof of Concept for a NATO Digital Library for Additive Manufacturing (codename: RAPiD-e). This new platform was successfully showcased at the Coalition Warrior Interoperability Exercise (CWIX) held at the Joint Force Training Centre in Bydgoszcz, Poland in June 2023. In one of the test cases, NSPA, at the request of the Ministry of Defence of Denmark, successfully 3D-printed on-site, a digital file owned and published by the British Army, , with all transactions executed through a smartphone.

Based on this success and the growing interest in the platform from NATO nations and the defence industry, NSPA was tasked to develop the existing Proof of Concept into a fully featured operational capability, as a result of ACT’s approval of additional phases for the project. Other planned features include integration with the NATO Codification system, the addition of secure and traceable transmission to protect Intellectual Property and support for low connectivity scenarios to enable the use of RAPiD-e on the frontlines.

NSPA has demonstrated its outstanding project management and business innovation capabilities through the successful development and showcase of the RAPiD-e Proof of Concept. Since the outset, RAPiD-e has attracted significant interest that is expected to continue given the approved additional phases, and the following ones already planned:

- Phase 2 of the project will allow additional nations to access and test RAPiD-e by the end of 2023. This will also include a focus on industry collaboration, and some industrial actors have already planned to integrate access to RAPiD-e into their own systems, to provide additional value to their customers. Phase 2 will also expand supported formats, including Subtractive Manufacturing.

- The US and UK armed forces have requested to test RAPiD-e during their joint military exercise Capstone 4 in March 2024, bridging a crucial interoperability gap.

- RAPiD-e will be showcased and tested again at CWIX in June 2024, which will include additional nations as test partners and a collaborative demonstration with Rheinmetall and potentially other industry partners.

- Mobile metal-based 3D printing testing through RAPID-e will be carried out by Nations supporting Ukraine.