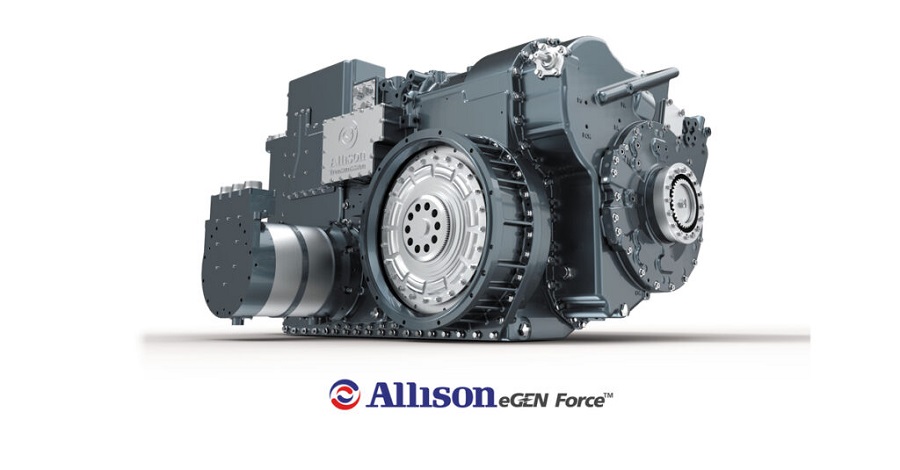

“This product is more than a transmission – it is a power distribution system featuring an electric motor and inverter for on-board vehicle power and parallel hybrid operation,” said Dana Pittard, Vice President, Defense Programs, Allison Transmission. “This enables engine-off mobility to reduce enemy detection – both acoustic and thermal – ideally increasing soldier survivability.”

Allison has combined its decades of experience with both combat vehicle and electric hybrid propulsion solutions to develop the new eGen Force system. Prior to initiating the design of the eGen Force, Allison leveraged voice of customer by conducting a comprehensive trade study based on more than 70 years of cross-drive development to select the optimal architecture for an electric hybrid combat vehicle with the goal of optimizing efficiency, performance, reliability and manufacturability. To reduce developmental risk, Allison has combined established parts from its X1100-3B1 transmission, used in the Abrams Main Battle Tank, with new components that follow proven design strategies for the gearing. The high efficiency range pack utilizes eight forward and three reverse gears providing an efficient 12:1 ratio coverage and generates 220 kilowatts of electrical power.

“We are very pleased with sub-system performance testing and validation,” said Michael York, Executive Director, Defense Engineering, Allison Transmission. “In October, the eGen Force begins dyne and engine stand testing followed by vehicle testing in early 2023. System and vehicle level integration expertise is a core competency and differentiator for Allison, and we are proud to deliver these next generation capabilities in partnership with our defense customers.”

Allison is working with American Rheinmetall Vehicles (ARV) to integrate the eGen Force into their OMFV offering. The ARV vehicle delivers best-in-class mobility and unmatched power in a highly maneuverable and modern chassis that will transform the way soldiers and squads accomplish their mission.