In search of a lighter armour, the European Defence Agency (EDA) launched a project on 20 October 2022 to use new advances in metallic materials for ballistic steels.

Known as the Additive Manufacturing of Metallic Auxetic Structures and Materials for Lightweight Armour, (AMALIA), the project aims to enhance the performance of ballistic and blast protections using auxetic structures, which become thicker when stretched or thinner when compressed. Making use of specific alloys developed for ballistic applications, this material can be tailored for the additive manufacturing process.

In response to a violent impact, the auxetic materials have the advantage of being denser in the strike zone and allow a higher energy absorption, offering more protection.

The AMALIA project, costing slightly less than € 5 million, is funded by seven EDA Member States (Italy, Czech Republic, France, Germany, Poland, Romania, Slovenia), led by RINA Consulting – Centro Sviluppo Materiali.

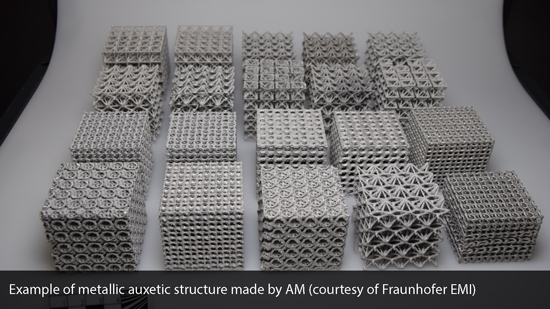

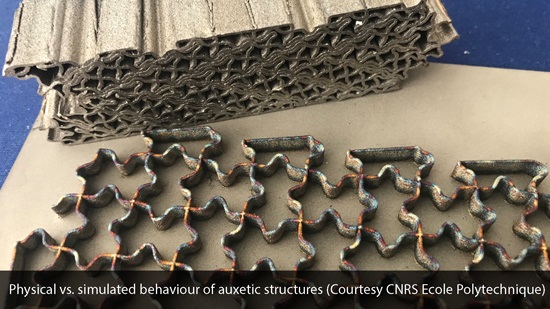

The state-of-the-art structures are still mainly at a theoretical level, involving numerical simulations. Several studies have assessed the positive effect of these structures on energy absorption, suggesting that auxetic structures can be used for protective equipment, including armour for military vehicles. However, due to the manufacturing difficulties of such structures, not many 3D metallic structures have been developed.

Some examples of parts with auxetic structures are made in aluminium, stainless steel and titanium alloys (EBM technology) but are still on a small scale.

The AMALIA project aims to explore technical issues related to the difficulties of manufacturing such auxetic structures using traditional manufacturing methods. Material development will also have an important role in producing alloys specifically developed for the additive manufacturing process by means of thermodynamic, kinetic and solidification tools.

The materials will be investigated to better understand the response of auxetic materials to static and dynamic impact loading conditions at different strains, an aspect not yet sufficiently explored.

The project will rely on extensive simulations, in order to test the ballistic properties of new auxetic structure topologies and fine tune the process parameters for the actual structures production.

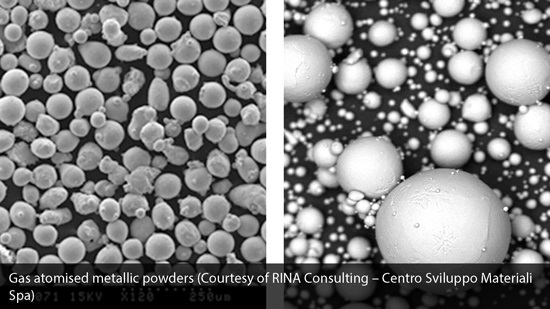

The properties of the additive manufactured part will be improved through gas atomisation, a process aiming at synthesizing high-quality metal powders with controlled particle sizes.